SPECIALITY HOTMELT

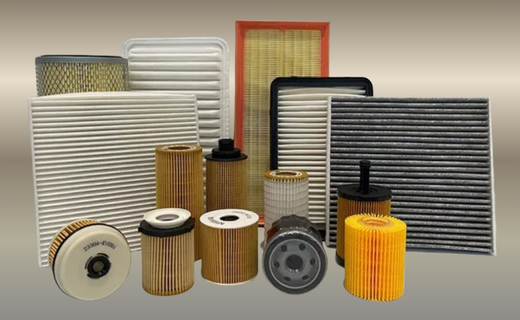

Hotmelt Adhesives for Air Filter assembly

Chemline provides Hot Melt adhesive for Airfilter / Mini pleat HEPA filter application for bonding of metalic mesh to various other filter media. Also suitable for assembly of peripheral components, woven and nonwoven, glass fibre media and sealing at critical points.

Salient Features

Suitable for plating equipment of different time and speed to meet requirement of different pleat gaps and for various filter media such as PP, Nylon, Polyester etc. Excellent toughness makes filter flexible and in shape. Good thermal resistance.

PACKAGING INDUSTRY

Hotmelts for Packaging and Converting Industry

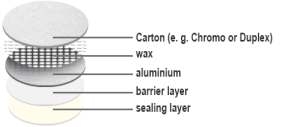

Chemline have hotmelt adhesives for Carton and Case Sealing. Also, we have hotmelts for Packaging and Conversion of Ice-Cream and Frozen Foods segments. Constantly endeavouring ourselves in innovation, Chemline especially develops Metallocene based hotmelt. This high performance adhesives has the characteristics of low odur, no charring, no stringing, high strength which can save cost and create better efficiency for the customers.

Salient Features

- Long / Short open time depends upon the applications

- Good Thermal Stability

- Low Odour, Creating pleasant environment

- Higher Mileage

- Suitable for various hotmelt machines like Robatech, Valco Melton, Nordson etc.

- Lower Energy Consumption

- Reliable Operations

HOTMELT PRESSURE SENSITIVE ADHESIVE FOR VARIOUS APPLICATIONS

Industrial Tapes

Medical Tapes

Tapes Variety

Label Stock & Holograms

FIBC Liner & Courier Bags

Chemline Pressure Sensitive hotmelt adhesive have wide applications such as Label Stock, Holograms, Courier Bags, Medical Tapes, Industrial Tapes & Liner attachment in Jumbo / FIBC Bags Chemline have two types of hotmelt glue for Tapes i.e. Tamper Evident (Permanant type) and Peelable Sealing types.

Salient Features

- Low Odour

- Stronger bond Strength

- Excellent Thermal Stability

- Suitable for spray and slot - die coatings

- No reduction in dry tack or storage both before and after use

Chemline provides a range of high performance, Exceptional Comfort and Cost-Effectiveness solutions of hotmelt Adhesives for nonwoven hygiene applications such as Baby Diapers, Feminine Care and Adult Incontinence.

Hotmelt Adhesives for Sanitary Napkins, Diapers and Panty Liners

Salient Features

- Low Odour

- Stronger bond Strength

- High Softness gives more comfortable fitting

- Excellent Thermal Stability

- Suitable for spray and slot - die coatings

- No reduction in dry tack or storage both before and after use

BEVERAGE INDUSTRY

Chemline hotmelt adhesives for bottle labelling has low viscosity which can be operated at low temperature and reduce label deformation. It has permanent tack that can bond label with less volume for various kind of plastic films and bottles such as PC, PET, PP, PE and straw attachment on Tetrapack. It gives bonding on Polyester to Paper/Board.

Salient Features

- Depend upon customer needs, we will provide Water White, White, Light Yellow adhesives

- Suitable for high speed machine like Krones, KHS, Siddle etc.

- No fibre formation during operation

Bottle Labelling

Tetra Pack - Lid Fixing

HOTMELT ADHESIVES FOR MATTRESSES

Foam to Foam Bonding & Spring Pocket Bonding

Salient Features

- It gives strong bond between foam to fabrics in Mattresses

- Excellent thermal stability

- Most suitable for pressure sensitive coating / Spray application for interior bonding of Automotive & Mattresses.

ASSEMBLY OF AUTOMOTIVE LAMPS, AUTOMOTIVE BATTERIES & INTERIOR WITH HOTMELT GLUE

Advantages

No Metalic Impurity after Testing in Sulfuric Acid @ 70 °C for 7 days. High Spreadibility, Better Bonding

Salient Features

It gives strong bonding between PC, PP, PMMA, ABC acrylate

Lamp Assembly

Battery Assembly

Interior Bonding

PC to PP Bonding

Automotive Application

SPECIALITY HOTMELT

Hotmelt Adhesives for WPP Bag Side Sealing

Hotmelt Adhesives for Shoe Fabric Lamination

Anti - Skid Carpet Back Coating and Palletization

Chemline provides Hotmelt adhesives for antiskid carpets and palletization which is solvent free, easily processed, fast curing, slight coating, good washability, excellent antiskid performance.

Salient Features

It is non-sticky after de-palletizing. High thmosiability and good flexibility. Suitable for Spray application.

Carpet Back Coating

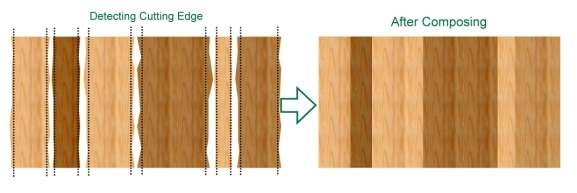

EDGE BANDING FOR WOOD & CORE COMPOSER

Chemline provides Hotmelt adhesives for manual and edge banding machines. It gives superior coverage, excellent finishing and long durable bond which is unaffected under extreme atmospheric condition. It is good for Hardwood, softwood, MDF, Also on Veneer, PVC Lamination, Melamine Board.

Salient Features

- Suitable for manual automatic edge banding machine

- Immediate good re-melting behavior

- High bonding and peel strength

- Unaffected with extreme hot climate

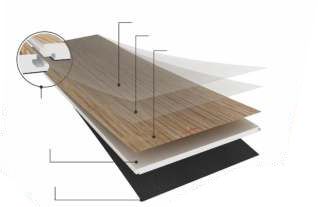

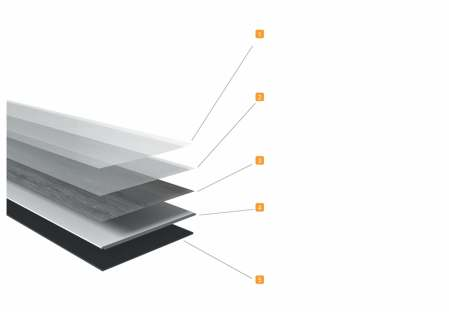

HOTMELT PRESSURE SENSITIVE ADHESIVE FOR SPC FLOORING

SPC Flooring Structure

Ceramic SPC Flooring Structure

Composition

- Durable UV Layer: ensures superior stain-resistant and water-proof performance, saving maintenance cost

- Wear Layer: transparent top layer: restore, colorful, easy to clean, protecting it from abrasion

- HD Decorative Layer: regardless of natural stone wood grain or other material you preferred, plentiful of pattern choice that will better showcase your personality

- SPC(Stone polymer composite) core: Prevent expansion and contraction of the flooring panel after installation

- EVAE(Ethylene-vinyl acetate) Foam Pad (Optional): Better sound absorption, anti-slip and comfortable to walk on

Characteristics

- Suitable for lamination of S.P.C. core to IXPE foam of S.P.C. floor assembly

- Strong bonding results in higher production

- Fast melting Characteristics

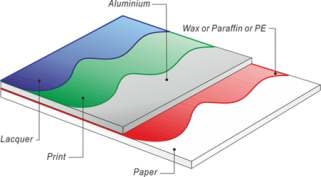

LAMINATION WAX

WAD Fixing

Lamination Wax

WAD Fixing

Lamination wax for WAD/Induction Sealing

- Gives good bond between foil and board.

- Gives complete Delamination of foil from board during induction process.

GEO - Textile

- Suitable for bonding between HDPE film and PP non woven

- Gives flexible coating with higher coverage.

Hot Foil Stamping

- Suitable for Foil Stamping.

- Higher coverage

HOTMELT ADHESIVES FOR VARIOUS APPLICATIONS

Hot Foil Stamping

Geo Textiles

Soap Wrapper Coating

Shrink Sleeve Tube Making

Toffee Wrapping & Butter Packaging

Confectionery Wrapping

Request a Quote Section

Get the Right Hotmelt Adhesive for Your Application

Our experts can recommend the most suitable formulation for your machine type, substrate, and end-use requirements.