QUIKBARRIER™

Barrier Coated Cup Stocks & Papers/Boards for Sustainable Food Packaging

Paper Bowls

Paper Cups

Coated Kraft Papers

Paper Plates

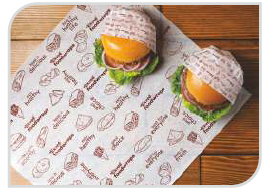

Food Wrapping Paper

Barrier Coated Food Wrapping Roll

Features

- Plastic free

- Water Repellent

- Oil & Grease resistant

- Heat sealable & non sealable

- PFAS free

- Bio compostable & repulpable, Cipet certified

- Good printability

- Odor less

- Environment friendly

- Suitable for food packaging/beverages

QUIKBARRIER™

Water Based Barrier Coatings for Sustainable Food Packaging

WPC4502HS / WPC4502NS

As global food packaging converters shift toward sustainable packaging, Chemline's QUIKBARRIER™ range of water-based barrier coatings and barrier-coated papers represent a future-ready solution, delivering reliable protection against moisture, oil, grease, and heat. This makes them ideal for food service applications such as paper cups, plates, pouches, containers, and wrapping papers. They not only match the functional performance of paper but also support global sustainability goals by being PFAS-free, plastic-free, compostable, and repulpable, as certified by Cipet.

Features

- Heat sealable & non sealable

- Excellent moisture barrier

- Solvent free

- Food contact safe

QUIKBARRIER™

Water Based Barrier Coatings For Sustainable Food Packaging

WPC4502HS / WPC4502NS

PAPER CUPS

Coated with QUIKBARRIER™ WPC4502 HS

KRAFT PAPER POUCHES

Coated with QUIKBARRIER™ WPC4502 HS

WHITE PAPER POUCHES

Coated with QUIKBARRIER™ WPC4502 HS

PIZZA BOXES

Coated with QUIKBARRIER™ WPC4502 NS

FOOD WRAPPING

Coated with QUIKBARRIER™ WPC4502 NS

PAPER STRAW

Coated with QUIKBARRIER™ WPC4502 HS

Request a Quote Section

Get the Right Barrier Coating for Your Packaging Application Our specialists can help you choose the ideal coating or adhesive for your substrate, equipment, and sustainability goals.